Southerly Boats

Buying a New Sailboat

12/12/20 07:57

Are you interested in buying or building a new boat but aren't sure where to begin? This video is the first in a new series about the design and build process of Distant Shores IV, the new custom-built aluminum e-boat we are planning to build. Determining criteria for your dream boat is the start of the process and Paul and his alter-egos, Traditional Paul and Future Tech Paul, hash out ideas together. Although entertaining, this video provides guidelines for determining important steps and considerations to help you make good decisions when searching for a new boat.

Comments

Battery Problems - Time for Lithium!

27/11/20 17:31

We finally get back to our boat in Panama after 7 months of lockdown and at first glance everything seems fine. Then we start going through lockers and systems thoroughly and problems start rearing their ugly heads. The biggest is that our 48 volt battery bank is dead! Time to replace with lithium. Then Hurricane Iota passes bringing stormy weather. Sheryl shows you our galley storage methods. The two Pauls discuss the Pandemic and the History of Yellow Fever in Panama.

Panama Canal Crossing

22/09/20 21:31

Come with us as we travel though the mighty Panama Canal! We made three videos on the crossing with details on preparing for the transit, working with an Admeasurer (who plans the passage for your boat),

The first in the series shows what you need to do to prepare your boat for a canal transit, what it costs, where best to prepare, and who you can get, to help you navigate the necessary paperwork and required inspections.

Entering the Panama Canal in our sailboat, we handle the first 3 locks up to Lake Gatun. We take you on the first leg of the transit from Colon to Lake Gatun. We also show you how to find line handlers, train your crew for line handling, how to set up your boat to meet requirements as well as protect it from possible damage during the transit. We show you how to work with the Canal Advisor who is assigned to come aboard your boat for the transit, how yachts are required to raft up and demonstrate some boat handling techniques for locking through.

In Part 3 we take you on the second and final leg of the transit across Lake Gatun, through the impressive Culebra Cut and descend 3 locks to Panama City on the Pacific Coast.

The first in the series shows what you need to do to prepare your boat for a canal transit, what it costs, where best to prepare, and who you can get, to help you navigate the necessary paperwork and required inspections.

Entering the Panama Canal in our sailboat, we handle the first 3 locks up to Lake Gatun. We take you on the first leg of the transit from Colon to Lake Gatun. We also show you how to find line handlers, train your crew for line handling, how to set up your boat to meet requirements as well as protect it from possible damage during the transit. We show you how to work with the Canal Advisor who is assigned to come aboard your boat for the transit, how yachts are required to raft up and demonstrate some boat handling techniques for locking through.

In Part 3 we take you on the second and final leg of the transit across Lake Gatun, through the impressive Culebra Cut and descend 3 locks to Panama City on the Pacific Coast.

Southbound to the Bahamas

01/02/20 09:29

Last time on Distant Shores we left Rudee Inlet in Virginia and sailed around Cape Hatteras and Cape Lookout - dealt with a fuel system problem that shut down our engine for the whole passage, and arrived at Beaufort in a gale with gusts near 40 knots. This time we're continuing further south sailing offshore from North Carolina towards Florida and the Bahamas.

Check out the episode below…

Check out the episode below…

Gale off Cape Lookout - We Lost Our Engine

18/01/20 07:18

This time on Distant Shores we make a 2 day passage around Cape Hatteras - deal with fuel problems that disable our engine - and face a gale as we sail past Cape Lookout to beat into rough seas towards Beaufort North Carolina.

When the tide is ebbing out of an inlet like this it causes onshore waves to rear up and break - and it's worse in the shallow waters around our narrow channel - now is the time to stay right in the channel as we motor out. If the motor did quit right now I would have to quickly pull out the Jib and use it to turn us and sail back in to the inlet. But we're lucky and it's 2 minutes more when we pass the outer channel marker that the engine does quit!! Yikes!

Check out the video below

When the tide is ebbing out of an inlet like this it causes onshore waves to rear up and break - and it's worse in the shallow waters around our narrow channel - now is the time to stay right in the channel as we motor out. If the motor did quit right now I would have to quickly pull out the Jib and use it to turn us and sail back in to the inlet. But we're lucky and it's 2 minutes more when we pass the outer channel marker that the engine does quit!! Yikes!

Check out the video below

Preparing to Sail South

04/01/20 12:28

This time on Distant Shores we're preparing our Southerly 480 sailboat for our journey south and on into the Pacific. We show you how to do a chain-splice, learn the technique for eating Chesapeake Bay Blue Crabs, attend the United States Sailboat Show and have a close encounter with a bridge going up the Severn River.

Part of the summer's plan for hauling out was to have a chance to touch up areas on the keel where the Coppercoat was incorrectly applied. This was warranty work covered by the manufacturer and required blasting to properly prepare the iron surface. In this case tiny crushed glass chips are blown in a concentrated stream using a powerful air compressor. Then coppercoat paint is applied. The copper is suspended in epoxy and is meant to last for a number of years - we'll report back.

We need to replace our chain and as part of the process we want to put a rope on the end of the chain. This was we would be able to drop our anchor in an emergency by easily cutting the rope.

We use an app called Animated Knots by Grog, which is excellent for Splices as well as knots.

Check out the video for the full splice!

Part of the summer's plan for hauling out was to have a chance to touch up areas on the keel where the Coppercoat was incorrectly applied. This was warranty work covered by the manufacturer and required blasting to properly prepare the iron surface. In this case tiny crushed glass chips are blown in a concentrated stream using a powerful air compressor. Then coppercoat paint is applied. The copper is suspended in epoxy and is meant to last for a number of years - we'll report back.

Splicing Rope onto Chain

We need to replace our chain and as part of the process we want to put a rope on the end of the chain. This was we would be able to drop our anchor in an emergency by easily cutting the rope.

We use an app called Animated Knots by Grog, which is excellent for Splices as well as knots.

Check out the video for the full splice!

Sailing North with the Gulf Stream

03/12/19 18:09

We're leaving the Bahamas using the Gulf Stream to make speed northbound.

This is our last sail on the amazing Bahamas shallow banks as we're preparing for the passage north to Beaufort and the Chesapeake Bay. For the first time we're going to sail right up the Gulf Stream and hope to use the current to add to our speed.

We are using the Predictwind software to get our weather and gulf stream forecasts via IridiumGO so we can receive updates even offshore. This is a first for us and worked very well. Although the updates can be pretty large even up to 1 MB or so it can be received over our connection if you choose a smaller forecast area for regular updates.

We catch a large Mahi-Mahi, bake bread, and set up the sails for fast downwind passaging with the current pushing us up to 11 knots.

When we pull in to Beaufort North Carolina we demonstrate using the current and wind to help get out of the dock in a tight situation.

This is our last sail on the amazing Bahamas shallow banks as we're preparing for the passage north to Beaufort and the Chesapeake Bay. For the first time we're going to sail right up the Gulf Stream and hope to use the current to add to our speed.

We are using the Predictwind software to get our weather and gulf stream forecasts via IridiumGO so we can receive updates even offshore. This is a first for us and worked very well. Although the updates can be pretty large even up to 1 MB or so it can be received over our connection if you choose a smaller forecast area for regular updates.

We catch a large Mahi-Mahi, bake bread, and set up the sails for fast downwind passaging with the current pushing us up to 11 knots.

When we pull in to Beaufort North Carolina we demonstrate using the current and wind to help get out of the dock in a tight situation.

Aground! Shallow Water Piloting in the Bahamas

10/09/19 17:22

Many of you have been asking why we love variable-draft Southerly Yachts. After-all, we've owned three of the them throughout the 30 years we've been cruising. So in this latest video, we answer your questions, giving you our completely biased view on Southerlies :-) as we sail from the Turks and Caicos Islands to cruise the shallow seas of the Bahamas, before Hurricane Dorian hits. We sail in company with other 6 other Southerly Yacht owners and demonstrate the freedom the variable-draft keels give us to explore shoal-draft anchorages and bays that deeper draft yachts can't get gain access to.

At the same time, we share our techniques for shallow-draft piloting in the islands, no matter what your boat draws. The Bahamas is one of our very favourite cruising grounds and in this video we show you why.

At the same time, we share our techniques for shallow-draft piloting in the islands, no matter what your boat draws. The Bahamas is one of our very favourite cruising grounds and in this video we show you why.

Understanding Marine Power Systems

04/08/19 16:29

Do you want to understand marine power systems better? Do you find marine power systems confusing? Are you trying to determine if your boat has enough power to run the equipment you’d like to install?

In this video series, we take you aboard our Southerly 480 sailboat, Distant Shores III, to help you understand what is involved in setting up a marine power system for your own boat.

In Part 1 of this new video series, we take you aboard our new Southerly 480, Distant Shores III, and start with the basics to help you understand what is involved in setting up a marine power system for your own boat.

In Part 2 of this video series, we create an electrical budget calculating our power use for various devices.

In this episode, we demonstrate our solar power system and Integrel on-engine generator and discuss how we use them together.

In this video series, we take you aboard our Southerly 480 sailboat, Distant Shores III, to help you understand what is involved in setting up a marine power system for your own boat.

Part 1 - Electrical Basics

In Part 1 of this new video series, we take you aboard our new Southerly 480, Distant Shores III, and start with the basics to help you understand what is involved in setting up a marine power system for your own boat.

Part 2 - Power Budgeting

In Part 2 of this video series, we create an electrical budget calculating our power use for various devices.

Part 3 - Solar Power & Generator on Distant Shores III

In this episode, we demonstrate our solar power system and Integrel on-engine generator and discuss how we use them together.

Warning Shallow Water!! A Field Guide to Identifying Southerly Yachts…

29/03/15 07:43

By Paul Shard, Copyright 2015. All rights reserved.

This morning we dropped anchor in Simpson Bay Lagoon on the lovely island of St Martin. Pretty views, excellent protection and central location close to everything! But before we were even able to get the anchor set and the snubber on we had already caused a Bavaria 42 to run aground! They were looking for a spot to anchor and saw us, on a 49 foot boat, in a large open spot with plenty of room to drop the hook near us. Unfortunately for them they did not recognize our boat is a shallow-draft Southerly and we were in a very shallow spot - that’s why it was empty. We have the keel up and are drawing just 2’10”. The water is just over 3 feet deep.

This patch of shallow water is marked on the chart but still every day we have boats either trying to anchor near us or trying to cut across the corner - and they run aground. Luckily it’s just mud, and the Bavaria unrolled their jib to heel the boat and reduce their draft. Unfortunatelly they headed directly towards us thinking that would get them back to the deep water. I called over to them to head the other way and they got off the mud.

Yacht Draft Comparison

Here are some boats in the 40-50 foot range… We are the longest with by far the shallowest draft. Anyone who owns a Hanse will suspect nearby boats are shallower than they are but people who own Island Packets often assume they are shallower than us! WRONG!

Over 800 Southerly Yachts have been built in the south of England and over there most people recognize them and know a Southerly might be in shallow water. But even in Chichester Harbour, just 1 mile from the factory, this monohull “took the ground” accidentally coming in too close to us on a falling tide.

Beachable

All Southerly yachts have been built with the ability to “take the ground”… here is a video we did as we purposefully sat on the bottom in the Bahamas and got back off the beach the next morning…

Identifying Southerlies

So here are a few images of different Southerlies built over the years to help you identify them. If you see one it might be in shallow water. This is a popular model called the Southerly 35RS - 35 feet long.

Below is a Southerly 100 - similar style to many of the older models.

Largest Southerly ever built! She is 57 feet long. Would you believe this boat, Rosetta, draws just over 3 feet?

Here is the Southerly logo - often on the hull or sails…

Secret Sauce

Here is the reason we can sail well (keel down) and still sneak into VERY shallow waters… this huge keel lifts up!

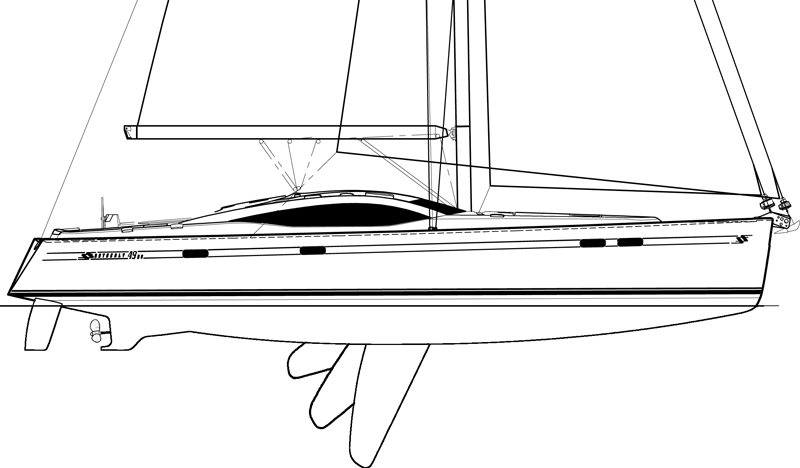

Here is the hull drawing… note the keel swings up to hide entirely in the hull…

So if you see Distant Shores II in an anchorage, please come and say hi! But don’t come and anchor near us until you have checked that there is enough water for your boat and that we aren’t in one of our special “shallow draft only” anchorages!

Adventures in Shallow Sailing

Check out some of our favourite shallow water sailing grounds in the Bahamas with this free “starter” episode of Distant Shores… you can download the whole 24 minute episode to view on all your devices…

Going to Windward

22/06/13 06:21

Its been said that "Gentlemen don’t go to windward"

Well they do if they are hoping to get to the "Caribbean Windward Islands". I think the idea is that gentlemen can wait a day or two for more favourable winds and hence avoid the need to beat to windward. This strategy actually does work in many temperate climates where winds come from a variety of directions. But here in the tropics the winds are much more predictable and come almost always from the east. Days and days of east winds, generally varying from 12-15 knots to 15-20 knots, and slightly ENE in the winter and E-ESE in the summer. So the gentleman who hopes to sail from Saint Martin to Martinique will be quite close-hauled for most of the journey.

We just finished the upwind journey from Saint Martin to Martinique over the past 3 weeks.

"St Martin to Nevis (63 nm) - great sail close hauled! Average 6.8 knots."

"70 miles Nevis to Deshais, Guadeloupe (70 nm) - we do this 2.5 hours less than a nearby 44 foot sailboat !"

"Sail upwind Deshaies to Portsmouth, Dominica (45 nm) - 6.5-7 knots at 45% apparent in 18-24 apparent wind 1.5-2 meter swell"

"Upwind Dominica to St Pierre, Martinique (49 nm) - 6.3 knots - seas 2-2.5 meters, apparent winds 24-30 knots"

Wind Strength

If the wind is around 15 knots the seas will likely be less than 2 meters. This makes the whole thing more "Gentlemanly"... Our first three days the winds were 14-15 knots on average and the seas less than 2 meters. We were close hauled at 45% apparent but that is a very good point of sail for the Southerly with her 10-foot draft when the variable-draft keel is down (2’ 10" draft with the keel raised). We can point as high as 30 degrees but of course would slow down somewhat and would have more trouble in the big seas. So for us 45% is a fine angle. We had a romping good sail and passed all the other boats we saw out there. There are a number of factors here, and if you are on the margin on some of them then the day isn’t going to be nearly so enjoyable. Here are some of the factors that effect windward ability...

Sails

Our sails are just 3 years old and in excellent shape. Old baggy sails can’t point efficiently to windward and will slow you down considerably. We were using our mainsail with one reef in it. The fully-battened mainsail in good shape will almost certainly beat a furling mainsail when close hauled. We have a "self-tacking" jib just 100% and quite flat cut. It is an excellent sail and in good shape. It is just Dacron however - nothing exotic. So if you have more modern sails you might go better to windward, if you have older sails or are using a bigger genoa reefed down then you will have more difficulty pointing.

Hull(s)

Not all boats are designed for close-hauled windward ability. Catamarans are commonly said to have more trouble going to windward and a number of our cruising friends on cats confirm this. The difficulty seems to be compounded in large seas as the two hulls hit the waves more often... But many monohulls are not that good going to windward. The depth of the keel helps, as does hull shape. A cruising boat with "shoal-draft" will not point as well as the same boat with a regular keel. In fact I think a modern cruising catamaran can perform as well to windward as most monohulls when not overloaded...

Loading

Regardless of boat design above, all boats will have more trouble performing to windward if they are overloaded. The problem with cruising boats is that it is very easy to overload them. A large stern arch bristling with solar panels, antennas, spare anchors, fishing gear, additional outboard motors etc, is a huge weight to have high and aft on a boat. Surfboards, jerry cans and more strapped to the lifelines are a big factor reducing stability and sailing ability. The designer didn’t plan for this and the performance will not match initial expectations! Catamarans are even more susceptible to this as they have a lot of interior space. It is a temptation to keep filling that space up, and as a cat gets lower in the water the bridge deck comes lower too. Then there are even more problems going to windward. I do not mean to point the finger at "cats". Looking around at the typical anchorage I think the cruising monohull is likely to be more overloaded than the average catamaran. So not to overload your cruising boat if you hope to achieve the performance you remember when you first got your boat - whether she is a catamaran or mono-maran :-)

Waterline

Comparing our previous boats, our old Classic-37 "Two-Step" had a sailing waterline length of less than 30 feet. Distant Shores II has a waterline of almost 48 feet as she sails to windward. This means she pitches much less, absorbs the waves more easily and is drier as well. Not much you can do about this one, but be aware if passage planning that a smaller boat will have a rougher ride, especially to windward. I know that as we sailed these past 2 weeks we were enjoying the sail and sitting in the mostly-dry cockpit. Remembering Two-Step, as I looked at some of the larger waves coming at us I thought how much wetter and less comfortable we would have been on Two-Step.

The extra waterline length also means higher speed. As we averaged nearly 7 knots on the first 3 days we cut a couple hours off boats that were struggling to make 5.5-6 knots upwind. Its 71 miles between Nevis and Guadeloupe and we took 11 hours (average 6.5 knots). For boats that averaged just 1 knot less that would take 2 hours longer. That meant we didn’t have to get going in the dark, still making it in before dusk at the lovely harbour of Deshaies.

Reefed jib sailing in 20 knots to windward - notice (nearly) dry decks

Limits on Comfort

The last log entry is for the crossing from Dominica to Martinique. Seas were higher at 2-2.5 meters (7-8 feet), the wind was up with a forecast of 20-24. We certainly saw those seas and higher in the turbulent zones near the headlands. Apparent wind was 24-30. In these conditions I decided to just fly our tough 100% jib. We could have flown a double reefed main as well but I was worried about higher gusts near the high headlands. So we took it easier and slowed down a bit. As we passed the gusty headland leaving Dominica we had a few rolls in the jib to reef even further. With just the jib we stood up nicely and still sailed at a reasonable 6-6.5 knots. So knowing the limits for your sail configurations, and how comfortable you can be in bigger seas is a factor too. As we were closer to our "comfort-limit" on that last sail I wanted to take it easy on the boat and her crew. After all we were completing the last leg on our journey to the "windward islands" so hopefully can crack sheets and enjoy some reaching coming up!!

The NEW BOAT!!!

12/03/10 02:54

Our new Southerly 49 is in the water! We have just come down to Itchenor in the south of England and are starting the process of moving aboard and getting her ready for the sailing season ahead.

Yesterday we took her out for her first sea trial and had an exciting sail. Wind was gusting over 25 knots and it is VERY cold! Spring is about 3-4 weeks behind schedule here in England.

Initial observations are that she is very quick. The extra waterline length over the 42 obviously gives us some extra speed but she is also a fair bit finer entry. She has just 6 inches more beam but 7 feet more length. She even has slightly lower freeboard which gives her a racy look. I’ll try to get some pictures of her from the dock today.

As soon as we left the dock we put up the mainsail and she was immediately running downwind at 8 knots!

Today its raining a bit so we’ll stay below and sort things out getting familiar with the new systems. This boat has an espar heater and its wonderful and warm! I made an anchor snubber by splicing an eye into a bit of 14mm line. Then just shackle the chainhook to the splice and I can give it a test today. So many little things to get her as ready as the 42 was!

Peaking inside

14/01/10 07:44

I shot a few pix of the interior... all wood is cherry.

This is the galley looking aft. Microwave and fridge are on the right.

Sheryl likes the new galley! Note wineglasses... day 2 of the show one was already broken so they were put away. Sometimes it is tough at the show with so many people aboard my new pride and joy! But 99.9% of visitors are respectful and we are very proud having people on board.

One thing cruisers always need more of is storage space... this is a separate bow locker. It is huge! Certainly room for all fenders, or spare sails. There is a ladder to climb down into it.

Behind me is the anchor chain locker with the door taken out.

Real teak decks. Beautiful and great to walk on at sea, I had always been leery of teak decks since the screws used to hold them down were a potential leak. Not here!! No screws are used in this system. The deck is assembled together and bonded THEN the whole piece is attached to the hull by vacuum bagging!

Sheryl sitting on the “Gin and Tonic” seats aft!

Raymarine’s new Hybridtouch plotter at the helm. Very cool! Touch screens are so convenient, but can be trouble in the rain since they think you are touching them. I had always thought they would be a problem on an outside unit. But the Raymarine units can be operated by buttons as well so you get the best of both worlds! Combined with the new Digital HD radar it will be a great package. I can’t wait to try it out on the water!!!

This is the galley looking aft. Microwave and fridge are on the right.

Sheryl likes the new galley! Note wineglasses... day 2 of the show one was already broken so they were put away. Sometimes it is tough at the show with so many people aboard my new pride and joy! But 99.9% of visitors are respectful and we are very proud having people on board.

One thing cruisers always need more of is storage space... this is a separate bow locker. It is huge! Certainly room for all fenders, or spare sails. There is a ladder to climb down into it.

Behind me is the anchor chain locker with the door taken out.

Real teak decks. Beautiful and great to walk on at sea, I had always been leery of teak decks since the screws used to hold them down were a potential leak. Not here!! No screws are used in this system. The deck is assembled together and bonded THEN the whole piece is attached to the hull by vacuum bagging!

Sheryl sitting on the “Gin and Tonic” seats aft!

Raymarine’s new Hybridtouch plotter at the helm. Very cool! Touch screens are so convenient, but can be trouble in the rain since they think you are touching them. I had always thought they would be a problem on an outside unit. But the Raymarine units can be operated by buttons as well so you get the best of both worlds! Combined with the new Digital HD radar it will be a great package. I can’t wait to try it out on the water!!!

At the London Boat Show

13/01/10 07:50

London has snow this winter and the boatshow is on!

Its been 3 years since we have been to any of the winter boat shows (since we have been sailing in the Caribbean;-) and I had almost forgotten how much fun they are and how good it feels to see boats when its cold and snowy out!

In fact 3 years ago at the London Boat show we signed up to buy our first Southerly. Now three years later we return to the show and enter the main haul to see the new 49 on the stand! Gosh were we excited when we first walked into the haul and there she was!!

We were lucky and got to have a chat with Rob Humphreys - who designed the 49 hull - Rob and his wife are on the left. Northshore Managing Director John Warne, and Marketing Manager Claire Horsman are on the right. Thats me and Sheryl with the huge grins in the middle. We are toasting the new boat!

Will post more tomorrow but for now heres a couple more picture showing some of the bigger stands at the show. We were again astounded at the size and effort to display the big power boats.

Note there are people standing on the upper decks of the 86 footer in the very back! The boats are huge to be in a building!

Remember this stand is all built for the show. The lower level lounge, upper viewing deck and all is constructed just for London Boat show. All built up from an empty concrete floor. Note also there is a car in the back of the powerboat!

Its been 3 years since we have been to any of the winter boat shows (since we have been sailing in the Caribbean;-) and I had almost forgotten how much fun they are and how good it feels to see boats when its cold and snowy out!

In fact 3 years ago at the London Boat show we signed up to buy our first Southerly. Now three years later we return to the show and enter the main haul to see the new 49 on the stand! Gosh were we excited when we first walked into the haul and there she was!!

We were lucky and got to have a chat with Rob Humphreys - who designed the 49 hull - Rob and his wife are on the left. Northshore Managing Director John Warne, and Marketing Manager Claire Horsman are on the right. Thats me and Sheryl with the huge grins in the middle. We are toasting the new boat!

Will post more tomorrow but for now heres a couple more picture showing some of the bigger stands at the show. We were again astounded at the size and effort to display the big power boats.

Note there are people standing on the upper decks of the 86 footer in the very back! The boats are huge to be in a building!

Remember this stand is all built for the show. The lower level lounge, upper viewing deck and all is constructed just for London Boat show. All built up from an empty concrete floor. Note also there is a car in the back of the powerboat!

Designer Rob Humphreys

17/09/09 06:42

A highlight of the Southampton show for me was meeting Yacht Designer Rob Humphreys. He has designed a great variety of boats over more than 35 years from racing sailboats to super-yachts. He has worked with Northshore for years improving upon the Southerly Swing Keel and he also designed the Southerly 42. Now he has designed the hull for the new 49. It was largely because I think his hulls are so good that I wanted to sign up for the new 49 even before I had a chance to sail the first one last month!

We had a chance to chat and Rob had a number of comments about the 49, and Southerly’s in general. Rob’s first comment was one I had realized when we sailed our 42 offshore. “Southerly’s are not constrained by the normal design restriction of needing to have a shallow keel. Most keels are a compromise since cruising boats can’t draw too much, or else they would be limited in their harbours and anchorages”. Our 42 draws 9 feet!!

This makes a very good upwind boat and a boat that is very stable at sea in big waves. Basically since the keel will be raised in shallow waters, Rob is free to make a deeper keel than any normal cruising boat or cruiser/racer. We find that swinging the keel down all the way makes the boat roll far less than other boats we have sailed on.

Southerly’s also have a very good motion at sea thanks to the high total ballast. Since the keel will be swung up and down, the boat needs to have sufficient ballast even when the keel is up for safe passaging. This is accomplished by the heavy “grounding plate”, in combination with the keel weight. The combination makes for a smoother ride in rough seas, but the long waterline length makes her fast as well. Here’s the keel and grounding plate for the new 49. HUGE!!

We also talked about the rudders. Having twin rudders means one will always be deeply buried, and since they are angled outward, the working rudder has a good angle as well. A second benefit is that when sailing downwind you have both rudders buried and extra stability.

Finally we discussed swinging the keel up. Its another advantage to the Southerly in that you can raise the keel to any desired position. So sailing downwind in calm seas you can raise it entirely to reduce drag. Or sailing in bigger seas where you still want keel stability to reduce roll you can raise the keel partially. Not only is drag reduced, but you also move the centre of lateral resistance aft making the boat easy to balance downwind. We did this much of the time crossing the Atlantic with the 42.

It was a privilege to meet Rob and now I am really looking forward to sailing the 49 in some more boisterous conditions to see what she can really do!!

We had a chance to chat and Rob had a number of comments about the 49, and Southerly’s in general. Rob’s first comment was one I had realized when we sailed our 42 offshore. “Southerly’s are not constrained by the normal design restriction of needing to have a shallow keel. Most keels are a compromise since cruising boats can’t draw too much, or else they would be limited in their harbours and anchorages”. Our 42 draws 9 feet!!

This makes a very good upwind boat and a boat that is very stable at sea in big waves. Basically since the keel will be raised in shallow waters, Rob is free to make a deeper keel than any normal cruising boat or cruiser/racer. We find that swinging the keel down all the way makes the boat roll far less than other boats we have sailed on.

Southerly’s also have a very good motion at sea thanks to the high total ballast. Since the keel will be swung up and down, the boat needs to have sufficient ballast even when the keel is up for safe passaging. This is accomplished by the heavy “grounding plate”, in combination with the keel weight. The combination makes for a smoother ride in rough seas, but the long waterline length makes her fast as well. Here’s the keel and grounding plate for the new 49. HUGE!!

We also talked about the rudders. Having twin rudders means one will always be deeply buried, and since they are angled outward, the working rudder has a good angle as well. A second benefit is that when sailing downwind you have both rudders buried and extra stability.

Finally we discussed swinging the keel up. Its another advantage to the Southerly in that you can raise the keel to any desired position. So sailing downwind in calm seas you can raise it entirely to reduce drag. Or sailing in bigger seas where you still want keel stability to reduce roll you can raise the keel partially. Not only is drag reduced, but you also move the centre of lateral resistance aft making the boat easy to balance downwind. We did this much of the time crossing the Atlantic with the 42.

It was a privilege to meet Rob and now I am really looking forward to sailing the 49 in some more boisterous conditions to see what she can really do!!

Going to Southampton

09/09/09 07:32

The Southampton Boat Show begins this weekend and Sheryl & I are going! We went in 2007 and quite enjoyed it. The show is a pretty big in-water boat show and its a nice venue.

This year Northshore will be introducing the new Southerly 49.

Of course we will also be dropping by the factory to see how our 49 is coming along!! I expect big changes since we saw it in early July. The 49 takes almost 6 months to build so we are just approaching the half-way point.

We also like the Boat Show in that it lets us look at all the latest equipment. We are just finalising the design on the electronics with Raymarine and very keen to see what is new since we set up our Southerly 42. New versions of the chartplotter, AIS, and radar are available I think - will report back!

We are also looking at LED lighting. This has been an area where I have been severely disappointed in the past :-( I have bought a number of LED bulbs in attempts to save power but almost all have been either very dim, sickly blue or have died prematurely. The picture above was my best of many bulbs tested - it is almost as bright as the 10watt halogen it replaced and is just slightly greener. Unfortunately it doesn’t work with the dimmer we have on the saloon lights.

I am forced to say LED replacement bulbs are not the way to go. I think LED lighting finally does work but at least for marine lighting it doesn’t make sense to buy a bulb to put in an old fitting. The best is to get an LED light bulb and fixture designed from the ground up for LED technology. Anyway, we shall see what’s at the show.

If any readers are going to be at the Southampton Boat Show, please come and say hi. Sheryl and I will be at the Northshore booth various times over the first weekend (September 10-12).

This year Northshore will be introducing the new Southerly 49.

Of course we will also be dropping by the factory to see how our 49 is coming along!! I expect big changes since we saw it in early July. The 49 takes almost 6 months to build so we are just approaching the half-way point.

We also like the Boat Show in that it lets us look at all the latest equipment. We are just finalising the design on the electronics with Raymarine and very keen to see what is new since we set up our Southerly 42. New versions of the chartplotter, AIS, and radar are available I think - will report back!

We are also looking at LED lighting. This has been an area where I have been severely disappointed in the past :-( I have bought a number of LED bulbs in attempts to save power but almost all have been either very dim, sickly blue or have died prematurely. The picture above was my best of many bulbs tested - it is almost as bright as the 10watt halogen it replaced and is just slightly greener. Unfortunately it doesn’t work with the dimmer we have on the saloon lights.

I am forced to say LED replacement bulbs are not the way to go. I think LED lighting finally does work but at least for marine lighting it doesn’t make sense to buy a bulb to put in an old fitting. The best is to get an LED light bulb and fixture designed from the ground up for LED technology. Anyway, we shall see what’s at the show.

If any readers are going to be at the Southampton Boat Show, please come and say hi. Sheryl and I will be at the Northshore booth various times over the first weekend (September 10-12).

Erie Canal & Construction update

04/08/09 07:15

We’ve been busy in the studio since we got back from England 2 weeks ago. We have a lot of TV shows to get out after a fabulous year sailing. This is always a fun time since we get to relive our trip as we edit the shows! I have been working on the trip from New York down the Oswego and Erie Canals to the Hudson and then down the 140 miles to New York City. This is a very fun trip and is the start of “The Way South” for anyone in the Great Lakes who wants to make the journey to Florida, the Bahamas or the Caribbean.

Here are a couple of pix of the trip...

Entering a lock as we go up the Oswego Canal

Investigating a lock from the old system - circa 1835

An interesting statue we saw ;-)

I do really enjoy editing the shows we shot since we get to relive the trip and hopefully provide useful information for viewers - who may be planning the trip themselves!!

While in the studio - the folks at Northshore are kindly sending along updates of the new 49 - here are a couple of shots of her in the shop. As you can see she is out of the mould now. Northshore like to leave the boats in the mould at least a few weeks until the glass has cured completely and the bulkheads are in to make her absolutely solid. Not all builders take such care.

The rudders are installed - not connected inside yet hence the unusual angle!

Most bulkheads are in already. Note the white coating over most of the inside of the hull. This is called a White Flo coat and is a special gelcoat that is meant to protect the inside of the hull and make it easier to clean. When we built Two-Step we had a lot of rough bits of fiberglass in the bilges that occasionally would catch a finger when you reached in or tried to clean up. It is a common problem with fiberglass boats - this should fix it.

Here are a couple of pix of the trip...

Entering a lock as we go up the Oswego Canal

Investigating a lock from the old system - circa 1835

An interesting statue we saw ;-)

I do really enjoy editing the shows we shot since we get to relive the trip and hopefully provide useful information for viewers - who may be planning the trip themselves!!

While in the studio - the folks at Northshore are kindly sending along updates of the new 49 - here are a couple of shots of her in the shop. As you can see she is out of the mould now. Northshore like to leave the boats in the mould at least a few weeks until the glass has cured completely and the bulkheads are in to make her absolutely solid. Not all builders take such care.

The rudders are installed - not connected inside yet hence the unusual angle!

Most bulkheads are in already. Note the white coating over most of the inside of the hull. This is called a White Flo coat and is a special gelcoat that is meant to protect the inside of the hull and make it easier to clean. When we built Two-Step we had a lot of rough bits of fiberglass in the bilges that occasionally would catch a finger when you reached in or tried to clean up. It is a common problem with fiberglass boats - this should fix it.

UK Visit to see 49 #1

21/07/09 07:53

Whew what a whirlwind! After a great passage up from the Bahamas to Beaufort in just 3 days we made a quick run through the ICW to Norfolk and the Chesapeake Bay to Solomons Island. Our plan is to base out of there for the summer while we are back in the studio working on the new TV shows. We will be editing the first 6 episodes by the end of September.

But before we got down to work we made a quick visit to the Northshore factory in England to see the first Southerly 49 - just launched and looking very racy down at the dock in Itchenor.

Luckily the boat was free for us to take her out for a spin! First impressions are great! We only had light winds but wow does she go. We managed 6 knots in just 7-8 knots of breeze!!! We scooted right past ALL the other boats out that day.

We also got a look at our new 49 in build in the factory. Just early stages yet but a thrill nonetheless to walk around in the hull

As usual the factory is humming - full to capacity with a waiting list for new boats. The “economic slowdown” doesn’t seem to have affected Southerly sales. I think the Southerly secret is the keel. They really are the only game in town for “variable draft cruising” with their lifting keel. They have perfected it after over 25 years of building these boats. And look at the keel. It isn’t a centerboard or any other kind of compromise keel. Here is the keel for our new 49. Beautiful. A true airfoil shape with over 10 foot draft!!

That means we can still sneak into the shallows since the boat draws just 2’10” with the keel swung up as it is in the picture above. So we can go places like the picture below...

But before we got down to work we made a quick visit to the Northshore factory in England to see the first Southerly 49 - just launched and looking very racy down at the dock in Itchenor.

Luckily the boat was free for us to take her out for a spin! First impressions are great! We only had light winds but wow does she go. We managed 6 knots in just 7-8 knots of breeze!!! We scooted right past ALL the other boats out that day.

We also got a look at our new 49 in build in the factory. Just early stages yet but a thrill nonetheless to walk around in the hull

As usual the factory is humming - full to capacity with a waiting list for new boats. The “economic slowdown” doesn’t seem to have affected Southerly sales. I think the Southerly secret is the keel. They really are the only game in town for “variable draft cruising” with their lifting keel. They have perfected it after over 25 years of building these boats. And look at the keel. It isn’t a centerboard or any other kind of compromise keel. Here is the keel for our new 49. Beautiful. A true airfoil shape with over 10 foot draft!!

That means we can still sneak into the shallows since the boat draws just 2’10” with the keel swung up as it is in the picture above. So we can go places like the picture below...

Stringers in hull

20/06/09 17:33

Next after moulding the hull is to reinforce it with a stringer grid. This is made of foam and will be heavily laminated with fibreglass. The fibre is the real strength forming a box section. You can see how many stringers are there down under the waterline.

In the middle you can see the keel box. The keel will be set in this and bolted in. When the keel is retracted it will swing up into this box. This is why no water comes into the boat from the lifting keel ;-)

Here is a shot from a few days ago crossing from Exuma Islands to Eleuthera - 40 miles of water only 15 feet deep. I went overboard to get film of the boat passing near a coral head (which was about 30 meters diameter) you can see the outline of the keel plate set into the bottom of the boat. The keel is mostly retracted. We like to keep it this way if we are exploring in shallow water. This way it acts as a safety in case we come into shallower water than we meant to. The keel will touch first and we slow down (since the keel weighs 3500 pounds it acts as a brake).

With the keel up and retracted the bottom of the boat is flat in the centre so you can beach and sit flat. Here is a shot from a week ago in the Exumas where we beached Distant Shores on a sandbank. The boat is sitting safely on the keel plate and the prop skeg. Its low tide. There is roughly 3 feet of tide in the Bahamas.

In the middle you can see the keel box. The keel will be set in this and bolted in. When the keel is retracted it will swing up into this box. This is why no water comes into the boat from the lifting keel ;-)

Here is a shot from a few days ago crossing from Exuma Islands to Eleuthera - 40 miles of water only 15 feet deep. I went overboard to get film of the boat passing near a coral head (which was about 30 meters diameter) you can see the outline of the keel plate set into the bottom of the boat. The keel is mostly retracted. We like to keep it this way if we are exploring in shallow water. This way it acts as a safety in case we come into shallower water than we meant to. The keel will touch first and we slow down (since the keel weighs 3500 pounds it acts as a brake).

With the keel up and retracted the bottom of the boat is flat in the centre so you can beach and sit flat. Here is a shot from a week ago in the Exumas where we beached Distant Shores on a sandbank. The boat is sitting safely on the keel plate and the prop skeg. Its low tide. There is roughly 3 feet of tide in the Bahamas.

Shallow Water Dreamboat!

01/06/08 15:52

We have been able to beach the boat for the first time and dry out on the sand. This is a feature of the Southerly and we found we could explore areas where other boats can't go. There are so many shallow islands without good all-weather anchorages (for deeper boats) but were great for us. We have been lifting the keel up to about 4 and a half foot draft and then venturing of the beaten track.If it is really shallow we can set the draft as low as 3 foot.

To beach the boat we have been looking around for a nice spot, then running up on the beach on a falling tide. Just be sure not to do it at the very highest in case you can't get off on the next high. This is apparently called being "neaped" by Robert - our Northshore expert. So, we pick a nice beach - protected from swells and with no rocks on the bottom - and run up to the beach at near high tide. We prepare our Fortress stern anchor and line on the aft swim platform and drop it 75 feet away as we head in. We head for the beach at about 2-3 knots and gently fetch up on the sand. Then I walk the anchor out forward to stop us drifting away if we want to stay for the night. In this case we will stay for 2 low tides and float off again in the next high.

So the verdict after a 6 week dream cruise in the Bahamas is that this is our perfect Bahamas boat!

After 5000 miles

01/05/08 22:34

I thought I would put down a few thoughts about the boat so far.

Passagemaking with a swing keel – most of our 5000 miles have been open ocean. Many people have asked about the swing keel on passage. Firstly I must say it has been great! The swinging part of the keel weighs over 3000 pounds and it does not rattle. People who have had other swing-keel boats ask this – but ours does not and I truly doubt that a keel this heavy could possibly rattle. It must be a problem with centerboarders where the keel is much lighter. The other thing with the keel is that having a 9-foot draft (keel all the way down) makes the boat VERY stable. At sea she rolls quite a bit less that Two-Step did. Similarly when we are at anchor we seem to roll less than other boats in the anchorages we have been in. Originally I thought we might use the keel more like a dinghy – raising it when going downwind and lowering it all the way for beating. But so far we have been happier having it down at sea – less rolling and a more comfortable motion. Downwind I do raise it a little bit but not much. Since it swings back and up ino the hull, raising it a little essentially just moves it aft but not much shallower. This has been useful making the boat sail downwind.

Docking with the bow thruster and rudders - in close quarters has taken a bit of getting used to. Mainly because our previous boat was so different - long keel, low and heavy. First of all you absolutely need the bow thruster I think. Otherwise she handles well over 1.5-2 knots with just the rudders but lacking the propwash she needs the thruster to handle in slow speeds. One big advantage I have found is that with the thruster she handles quite well in reverse as well as forward. Many boats (including our old "Two-Step") did not go in reverse. So in summary, I think she handles quite well in close quarters. We have now gone into 40-50 different docks/marinas and had no problems. One other idea is to use the keel. With the keel up she slides sideways in turns. Keel down she tracks nicely and turns well. Keel half way up her bow blows off the wind. I am getting better at using the keel like this to help manoeuvrability in close quarters. One funny situation we had last week involved getting into a slip with pilings. We pulled into the slip and were trying to grab the pilings when we ran aground on the mud. Now we had time to get the lines on the pilings sorted out. When everything was sorted we raised the keel and moved into the slip. Kind of like having a parking brake!

Tropical Southerly – I absolutely love the pilothouse/raised saloon on the Southerly 42. Being able to see out at anchor is great, and at sea I think it is a big part of the reason I don't get seasick at all on the new boat. But the problem with the big windows is the sun heats up the boat. We did not get curtains done by the factory, perhaps we should have. Now we are installing “Fifertex” curtains and that seems to do the trick. I have also added 5 fans throughout the boat. The Hella 2-speed “Turbo” fans are great. Antifouling has been not the greatest. The factory put on International's Uno which is not available over here. In the Caribbean grass fouling seems to be a problem. The local antifoulings all tout some sort of wonder cure for it. I guess you can't hope for a perfect coating that will work well everywhere. And the antifouling has all fallen off around the bow thruster fairing. We will replace it when we dry out for the first time in the Bahamas...

Heading to the Bahamas – We are SO EXCITED to be heading back to our favourite cruising grounds – the Bahamas! We will be there for most of May and early June – a very good time to cruise these lovely islands. The last time we were there I vowed I would come back with a shallower boat and really explore. We are doing it. When we talk to veteran Bahamas experts they always ask how much we draw. When we say 2 foot – 10 they are jealous! Looking over the charts I have planned out whole new island groups e can now visit that were not available to us with our previous 6-foot draft. I will post some pictures as soon as we can!!

Launch!!!

30/11/07 03:15

She's in the water. Sea trialled and we are off!!

From Itchenor (South coast of England not far from Portsmouth) we set off and did a marathon to Falmouth, crossing the bay of Biscay, and down the Spanish/Portuguese coasts to get away from the Northern winter. Here are a few quick pix of the launch and sea trials. I am going to keep the blog going (more frequently now we have a bit of breathing room) with updates on new equipment and our experiences with the new boat and her systems.

Out of the Factory - wooo hoo!

Mast goes up right in front of the factory

On to the travel trailer already rigged

Travel trailer loads to the marine railway.

With 5 meter tides we had to be ready by 1400 or wait till next day

From Itchenor (South coast of England not far from Portsmouth) we set off and did a marathon to Falmouth, crossing the bay of Biscay, and down the Spanish/Portuguese coasts to get away from the Northern winter. Here are a few quick pix of the launch and sea trials. I am going to keep the blog going (more frequently now we have a bit of breathing room) with updates on new equipment and our experiences with the new boat and her systems.

Out of the Factory - wooo hoo!

Mast goes up right in front of the factory

On to the travel trailer already rigged

Travel trailer loads to the marine railway.

With 5 meter tides we had to be ready by 1400 or wait till next day

Construction update

12/10/07 08:45

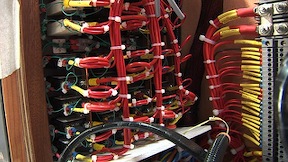

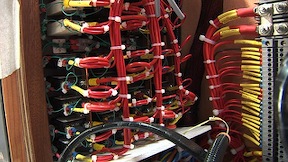

We just had another visit to the Northshore yard in Itchenor. "Distant Shores" (the new boat) is coming along great. Right now the final electrical and mechanical systems are going in and we met with David Payne of Mastervolt to inspect the electrical systems. As a cruising boat this couldn't be further from Two-Step. "Distant Shores" has a completely modern and advanced electrical system including a Generator, charger/inverter, isolation transformer, and triple the battery capacity of Two-Step. For more info on the electrical system see my blog entry on that.

The Northshore team are doing a really great job on the boat! Having built our first boat I have an appreciation of the thought and work that goes into building a boat. Ian, the engineer doing the installs of electrical and electronic gear is just excellent. I am afraid to say I would have been wasting time trying to figure out how to do something that Ian can do much more effectively. They have done almost of this stuff before and even if we have some new combination of gear to be fit in, Northshore's background of having built over 700 boats means some people there have experience with the right way to do things. No corners are being cut.

As an example - we are having Mastervolt AGM batteries fitted for both the main ships bank and also the generator and engine starting battery. CE and ABYC standards state that batteries should be in vented lockers. But this regulation was obviously intended for standard flooded batteries - not AGM or Gel cells which are sealed and do not vent gas while charging. I myself might have been tempted to install the AGM batteries and not bother with the vents - but not Northshore. They have done the best job I have ever seen on a vented battery box - running high quality breather tube to a beautiful stainless vent in the transom.

The whole boat is being built to that standard. Take a look at the back of the main electrical panel. Beautifully installed and so tidy it will be a joy to maintain this. Mark - who designs the electrical systems at Northshore has worked there for 27 years. The work he is doing is excellent and the systems shows the knowledge they have amassed over the years. In fact many people have been working there for more than 2 decades.

The whole boat is being built to that standard. Take a look at the back of the main electrical panel. Beautifully installed and so tidy it will be a joy to maintain this. Mark - who designs the electrical systems at Northshore has worked there for 27 years. The work he is doing is excellent and the systems shows the knowledge they have amassed over the years. In fact many people have been working there for more than 2 decades.

Next big milestone will be to put the deck on. So far the deck has been separate, and equipment is being installed on it as well. It will stay off until the last minute. It makes it much easier to do installations of large or heavy equipment since the overhead crane can be used. We shot this last visit when Ian was fitting the generator.

Next big milestone will be to put the deck on. So far the deck has been separate, and equipment is being installed on it as well. It will stay off until the last minute. It makes it much easier to do installations of large or heavy equipment since the overhead crane can be used. We shot this last visit when Ian was fitting the generator.

But now the launch is getting closer and much of the work in the hull is complete. So the deck install is imminent! Stay tuned!

The Northshore team are doing a really great job on the boat! Having built our first boat I have an appreciation of the thought and work that goes into building a boat. Ian, the engineer doing the installs of electrical and electronic gear is just excellent. I am afraid to say I would have been wasting time trying to figure out how to do something that Ian can do much more effectively. They have done almost of this stuff before and even if we have some new combination of gear to be fit in, Northshore's background of having built over 700 boats means some people there have experience with the right way to do things. No corners are being cut.

As an example - we are having Mastervolt AGM batteries fitted for both the main ships bank and also the generator and engine starting battery. CE and ABYC standards state that batteries should be in vented lockers. But this regulation was obviously intended for standard flooded batteries - not AGM or Gel cells which are sealed and do not vent gas while charging. I myself might have been tempted to install the AGM batteries and not bother with the vents - but not Northshore. They have done the best job I have ever seen on a vented battery box - running high quality breather tube to a beautiful stainless vent in the transom.

But now the launch is getting closer and much of the work in the hull is complete. So the deck install is imminent! Stay tuned!

Southampton Boat Show & Construction update

30/09/07 07:38

Launching is scheduled for just 4 weeks from now!! To say we are excited is a massive understatement!! Right now we are filming in the southwest of England - last weekend sailing on an 82 year old pilot cutter in gorgeous Falmouth Harbour - more to follow as we try to get out a newsletter....

We will be setting sail from England in early November and getting ready for our 4th Atlantic crossing. Check the schedule for opportunities to join us on the new boat for the inaugural season!

Attaching the keel!

03/08/07 07:45

Today the keel was attached. In the old days there was a celebration when you laid the keel of a new boat - and this feels the same! With the Southerly the keel is in two pieces. The grounding plate and the keel itself. In this picture the swing keel is in the up position and ready to have the hull put on top. The hull is up in slings ready to be lowered in place. I have included all the pictures to show how it is done.

The bottom of the hull is moulded with an inset shape to take the keel plate. You can also see the moulded slot into the hull for the keel when it is raised up. This picture also shows the width of the keel plate. Bolts are widely spaced giving tremendous strength.

Here's a detail showing the plate and the hull moulding insert. The design of the boat allows her to dry out sitting on her keel. You can see she will sit on this grounding plate when she is aground - much safer than if she just sat on the fiberglass of the hull.

Final checking of the fit.

Keel installed and all done.

That's it for today... now back to editing Distant Shores! Sheryl and I are in the studio for the next few weeks until flying to the UK in September.

Paul

The bottom of the hull is moulded with an inset shape to take the keel plate. You can also see the moulded slot into the hull for the keel when it is raised up. This picture also shows the width of the keel plate. Bolts are widely spaced giving tremendous strength.

Here's a detail showing the plate and the hull moulding insert. The design of the boat allows her to dry out sitting on her keel. You can see she will sit on this grounding plate when she is aground - much safer than if she just sat on the fiberglass of the hull.

Final checking of the fit.

Keel installed and all done.

That's it for today... now back to editing Distant Shores! Sheryl and I are in the studio for the next few weeks until flying to the UK in September.

Paul

Our New Boat being Built!!!

17/07/07 13:58

Sheryl and I have just got back to the studio from the spring filming in Italy and this morning received some picture from the yard at Northshore where the new boat is being built! How exciting!!! I just had to share some of the images with you.

Sheryl and I have just got back to the studio from the spring filming in Italy and this morning received some picture from the yard at Northshore where the new boat is being built! How exciting!!! I just had to share some of the images with you.Here is the Hull mould. The boat is moulded then a bunch of structure is put in before the mould is removed. This is so the hull is strong before the mould is taken off. So the plant is putting in bulkheads and stringers (lengthwise stiffeners). These will all be glassed in place.

The hull mould you see is carefully cleaned and then waxed on the inside. Then the gelcoat is sprayed in. So, the first part of the boat to be built is, somewhat bizarrely, the gelcoat (like paint). Then fibreglass is applied to the gelcoat in layers according to the designers specification until the desired thickness has been reached. Then coring is applied where specified - in this case above the waterline. Then the grid of stiffeners and finally the bulkheads.

Northshore has two facilities. The one pictured here is in Havant, and here they do all the fibreglass moulding. Then the boat will be trucked a few miles around to the main workshop in Itchenor (South England Near Chichester). This is the main Northshore headquarters where they complete and also launch the boat.

Northshore has two facilities. The one pictured here is in Havant, and here they do all the fibreglass moulding. Then the boat will be trucked a few miles around to the main workshop in Itchenor (South England Near Chichester). This is the main Northshore headquarters where they complete and also launch the boat.In the moulding shop in Havant they are also making the small mouldings that will be the two heads. These are normally made as a single moulding since it means they are waterproof - just like a built-in shower stall in a house. So here they are fitting the forward head moulding in place!

In the middle of the hull you can see a tall fibreglass structure. This is the keel casing. Since it is a lifting-keel boat the keel needs a place to retract into. But the keel will not be added until the boat has been trucked to Northshore in Itchenor.

In the middle of the hull you can see a tall fibreglass structure. This is the keel casing. Since it is a lifting-keel boat the keel needs a place to retract into. But the keel will not be added until the boat has been trucked to Northshore in Itchenor.Anyway, as you can imagine, Sheryl and I are VERY EXCITED about this. The new boat is a real thing!!

I will post more pictures as soon as they are available!

Cheers!!

Paul

This is the deck mould with the finished deck still on the mould.